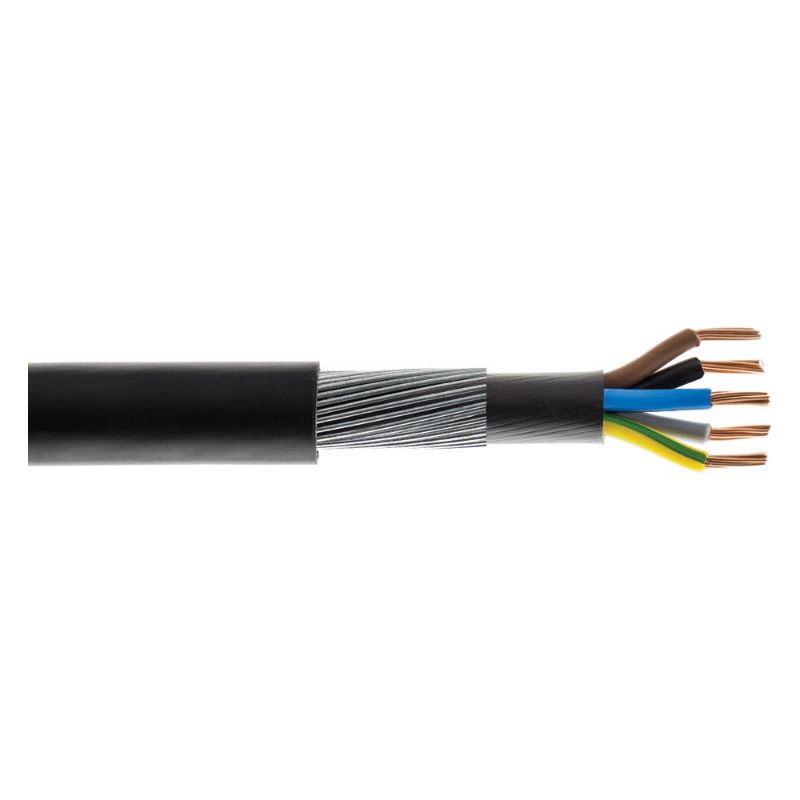

Armoured cables are an essential component of electrical and construction projects, offering durability, protection, and reliable electrical transmission. As an electrical wholesaler, it's crucial to understand the various types of armoured cables, their applications, and how to select the right one for different projects. In this comprehensive guide, we'll explore the types and applications of armoured cables, highlight key factors to consider when choosing them, and provide essential tips for ensuring safety and compliance. We'll also include links to specific armoured cable products available in our inventory.

Types and Applications of Armoured Cables

LSF SWA Cable:

- Example Products: 6943H2.5, 6943H6.0, 6945H35.0, 6945H6.0, 6943H10.0, 6945H16.0, 6943H16.0

- Low Smoke and Fume (LSF) Steel Wire Armoured (SWA) cables are designed to emit minimal smoke and fumes in case of a fire. They are commonly used in areas where fire safety is a top priority, such as public buildings, hospitals, and transportation hubs.

Screened SY Flex Cable:

- Example Products: SY3X16, SY3X10, SY3X2.5, SY3X1.5, SY3X6, SY3X4

- Screened SY Flex cables are flexible, screened cables suitable for applications that require resistance to mechanical stress and electromagnetic interference (EMI). They are often used in machinery, automation systems, and industrial installations.

Key Factors for Selecting Armoured Cables

Environmental Conditions:

- Consider the environmental factors such as temperature, humidity, and exposure to chemicals. LSF SWA cables are ideal for areas with fire safety concerns, while screened SY Flex cables are suitable for harsh industrial environments.

Voltage Rating:

- Determine the voltage requirements of your project to select cables with the appropriate voltage rating. Always ensure compatibility between the cable's voltage rating and the electrical system.

Cable Size and Core Count:

- Choose cables with the correct size and core count based on the current load and the number of conductors needed for the application.

Insulation and Sheathing:

- Evaluate the type of insulation and sheathing required for protection against moisture, abrasion, and chemicals. Different cable types offer varying levels of protection.

Compliance with Regulations:

- Ensure that the selected armoured cables comply with relevant industry standards and regulations to guarantee safety and performance.

Tips for Ensuring Safety and Compliance

Installation by Professionals:

- Armoured cables should be installed by qualified electricians who are knowledgeable about the specific requirements and safety procedures associated with each cable type.

Regular Inspection and Maintenance:

- Perform regular inspections to identify signs of wear, damage, or corrosion. Address any issues promptly to maintain cable integrity.

Documentation:

- Keep comprehensive documentation of cable installations, including cable type, specifications, and compliance records, for future reference and maintenance.

Selecting the right armoured cable is crucial for the success and safety of any electrical project. Understanding the types and applications of armoured cables, considering key factors during selection, and adhering to safety and compliance guidelines are essential steps. By following these guidelines, you can confidently choose the most suitable armoured cables for your projects, ensuring reliability and peace of mind.

For specific armoured cable products, please explore our inventory [insert product links]. If you have any questions or require further assistance, our team of experts is here to help you make informed decisions for your electrical needs.